The new cage would be built out of Chromoly which is both a stronger and lighter material than the steal used in the old roll bar.

The pictures show the weight difference in the stock roll bar and the metal used for just the roll bar section of the new cage.

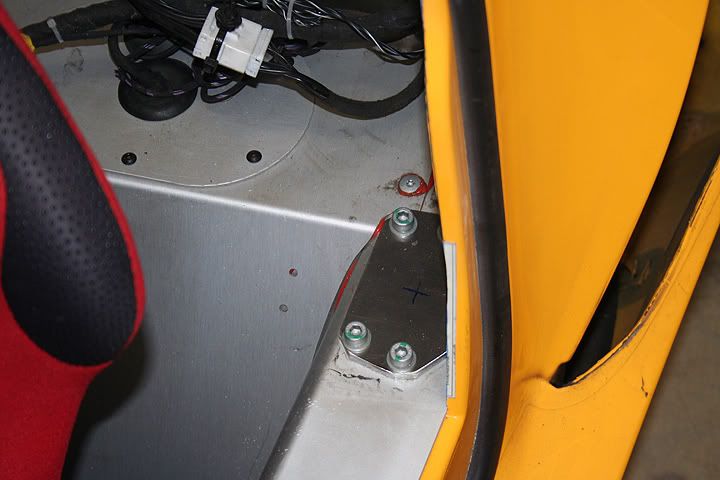

Since we weren’t going to have all the attachments that the old roll bar had, we could save a little more weight by keeping the tubing all the same diameter and leaving out all the unwanted brackets. This also gave the cage a much cleaner look. The last key benefit to the new cage is the additional bracing incorporated into it. With the diagonal cross braces and door/front kicker bars the Spyder now had something a little more suiting.

While the car was away, we still had the body to play with. With a little “plastic surgery” we would have a body to better fit the more serious, muscular looking chassis. Going into this project, the goal was to “simplify and add lightness”. This means removing unnecessary luxuries where possible and only replacing them with lighter parts when necessary. On a track car you really don’t need a trunk (Lotus certainly felt the same way with the S1 Motorsport Elise) so that had to go.

Now we had this big hole in the clam and thought, what better way to take advantage of the situation then to remove more fiberglass? What we ended up with was a spectacular view for any driver who might be following the car on the street or track.

Some where along the road the question of “how do you wash a car with no top” came up? We had to think about that one for a while, but I think our solution is even more efficient than the old traditional way.

The good news is it can be done even though we don’t actually have the car in our possession.

Chromoly Cage = 38lbs.

Stock Roll Bar = 17lbs.

Weight Removed From Clam = 10lbs.

Weight Added By Cage = 21lbs.

Weight Added By Cage = 21lbs.

Special thanks to our sponsor Burke Built Motorsports! For more information on Burke Built Motorsports, visit their website at: http://www.burkebuilt.net/

Notes: Another short project we undertook while the car was out was filling the stock transmission mounts with Polyurethane. It wasn't that difficult to do since the car was already on the lift with the clams off. It resulted in much better response and less engine movement for a very low cost.